For manufacturers focused on long-term efficiency, reduced downtime, and superior product quality, carbide heading dies are unequivocally worth the higher initial investment. While the upfront cost of tungsten carbide dies significantly exceeds that of traditional tool steel, their exceptional durability, wear resistance, and ability to hold tight tolerances over millions of cycles result in a lower Total Cost of Ownership (TCO). The investment pays for itself through drastically reduced tool changeovers, minimized machine downtime, lower scrap rates, and consistently higher-quality finished parts, making it a strategic decision for high-volume and high-precision production environments.

Table of Contents

- What Exactly Are Carbide Heading Dies?

- The Core Dilemma: Upfront Cost vs. Long-Term Value

- A Head-to-Head Comparison: Carbide vs. Traditional Steel Dies

- Beyond the Price Tag: Calculating the True Cost of Ownership (TCO)

- When is the Investment in Carbide Heading Dies a Clear Winner?

- Making the Right Choice: Partnering with an Expert Die Manufacturer

- Conclusion: Shifting Perspective from an Expense to a Strategic Investment

- Frequently Asked Questions (FAQ)

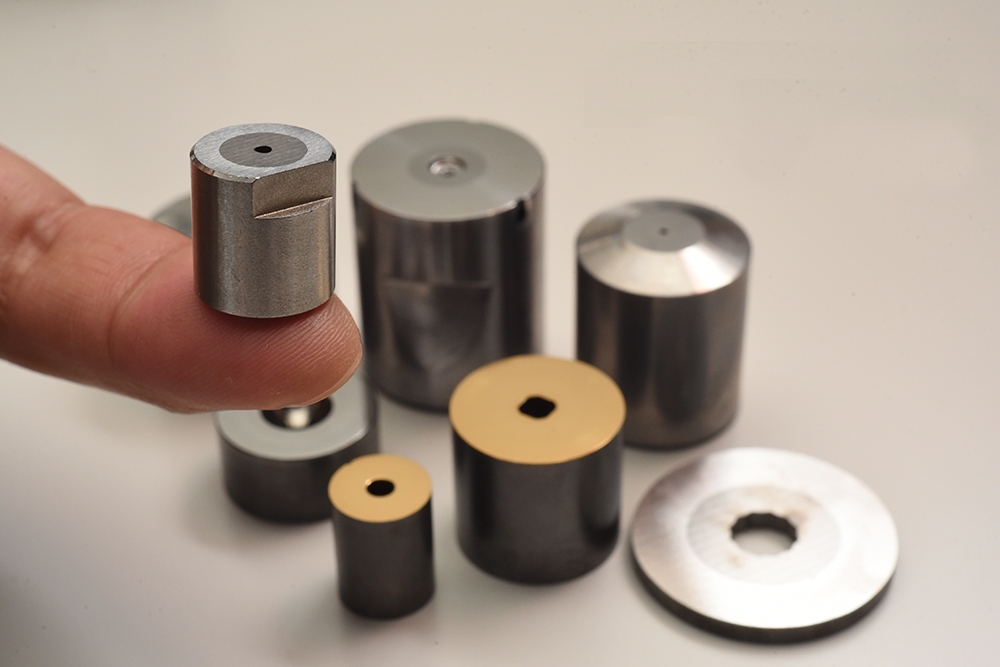

What Exactly Are Carbide Heading Dies?

Before diving into a cost analysis, it’s crucial to understand what makes carbide dies different. Carbide heading dies, often referred to as tungsten carbide (WC) or cemented carbide dies, are precision tools used in cold forming and heading machines to shape metal wire into components like screws, bolts, and rivets. Unlike dies made from conventional tool steel, carbide dies are a composite material. They are manufactured through a process called powder metallurgy, where microscopic particles of tungsten carbide (an extremely hard ceramic) are fused together with a metallic binder, typically cobalt (Co). This unique composition gives them a combination of properties that are simply unattainable with steel: immense hardness, exceptional wear resistance, and high compressive strength.

The Core Dilemma: Upfront Cost vs. Long-Term Value

The primary hesitation for any business considering a switch to carbide tooling is the initial expenditure. There is no denying it: a carbide heading die can cost several times more than its high-speed steel (HSS) or tool steel equivalent. This price difference often leads to a short-term-focused decision to stick with the cheaper option. However, this perspective views the die as a disposable consumable rather than a long-term production asset. The true financial picture only emerges when you shift the focus from the initial price to the overall value and long-term cost. This involves analyzing the entire production cycle, including downtime, labor costs, scrap rates, and the tool’s effective lifespan.

A Head-to-Head Comparison: Carbide vs. Traditional Steel Dies

To fully grasp the long-term value, a direct comparison of key performance indicators is essential. The differences in material properties directly translate into significant operational and financial outcomes on the factory floor.

| Feature | Tungsten Carbide Dies | Traditional Tool Steel Dies (e.g., HSS) |

|---|---|---|

| Durability & Lifespan | Extremely high. Can last 10 to 50 times longer, producing millions or tens of millions of parts. | Moderate. Requires frequent replacement, especially in high-volume applications. |

| Wear Resistance | Exceptional. Highly resistant to abrasion, galling, and friction, maintaining its profile for longer. | Good, but wears down progressively, leading to dimensional inaccuracies. |

| Precision & Tolerance | Maintains tight tolerances over its entire lifespan, ensuring consistent part quality. | Tolerances can drift as the die wears, increasing the rate of out-of-spec parts. |

| Production Speed | Allows for higher machine speeds due to better heat resistance and lower friction. | May require lower speeds to manage heat buildup and prevent premature wear. |

| Downtime | Significantly reduced due to far fewer tool changes. | A major source of downtime due to the need for frequent replacement and setup. |

| Initial Investment | High | Low |

| Total Cost of Ownership | Low over the long term. | High over the long term due to recurring costs. |

Durability and Wear Resistance

The standout advantage of tungsten carbide is its incredible hardness, typically ranging from 88 to 94 on the Rockwell A scale (HRA). This makes it immensely resistant to abrasive wear from the constant flow of metal wire. While a steel die might start showing signs of wear after producing a hundred thousand parts, a carbide die can often produce millions of pieces before needing to be serviced or replaced. This longevity is the cornerstone of its value proposition.

Precision and Tolerance Maintenance

In modern manufacturing, consistency is key. As a steel die wears, its internal geometry changes. This dimensional drift means that the first part produced is slightly different from the 50,000th part. This can lead to quality control issues and rejected batches. Because carbide wears at a vastly slower rate, it maintains its critical dimensions for a much longer period. This ensures that the millionth part produced is virtually identical to the first, guaranteeing a higher level of quality and process stability.

Production Speed and Efficiency

The superior material properties of carbide, including its high thermal conductivity and low coefficient of friction, allow machinery to be run at higher speeds without risking premature tool failure. Faster machine cycles mean higher throughput and greater overall productivity. Trying to run a steel die at these elevated speeds would lead to rapid overheating and catastrophic failure, negating any potential gains.

Beyond the Price Tag: Calculating the True Cost of Ownership (TCO)

The most compelling argument for carbide dies is found when you analyze the Total Cost of Ownership (TCO). This calculation includes not just the initial purchase price but all associated costs over the tool’s life. It reveals the “hidden” expenses that make cheaper steel dies far more costly in the long run.

The Hidden Costs of Frequent Tool Changes

Every time a machine is stopped to replace a worn-out die, you incur multiple costs. First, there is the direct labor cost of the technician or operator performing the changeover. Second, and more significantly, is the cost of lost production. A machine that is not running is not generating revenue. If a steel die needs to be changed 10 times more often than a carbide die, you are multiplying that unproductive downtime by a factor of 10.

How Downtime Devastates Your Bottom Line

Unplanned downtime is a major profit killer in any manufacturing operation. With steel dies, tool failure can be unpredictable, leading to sudden halts in production that disrupt schedules and delay customer orders. The reliability of carbide dies allows for predictable maintenance schedules and vastly reduces the frequency of unplanned stops. This stability in production is a significant, though often unquantified, financial benefit.

Scrap Rates and Material Waste

As a steel die wears and its tolerances begin to drift, it starts producing parts that are out of specification. These parts must be scrapped, representing a total loss of raw material, machine time, and labor. Because carbide dies maintain their precision for so long, the scrap rate due to tool wear is dramatically reduced, leading to more efficient use of materials and a higher yield of acceptable parts.

The Impact on Final Product Quality

The consistency provided by carbide tooling directly translates to a higher-quality end product. For industries like automotive, aerospace, and medical devices, where component failure is not an option, the reliability and precision of carbide-formed parts are non-negotiable. Using carbide dies can enhance a company’s reputation for quality and reliability, which is an invaluable business asset.

When is the Investment in Carbide Heading Dies a Clear Winner?

While carbide offers immense benefits, there are still scenarios where steel might suffice (e.g., very short-run prototypes). However, the investment in carbide becomes an obvious and highly profitable decision in the following situations:

- High-Volume Production: If you are producing hundreds of thousands or millions of the same part, the longevity of carbide will deliver an undeniable ROI.

- Forming Hard or Abrasive Materials: When working with stainless steel, titanium, or other challenging alloys, steel dies will wear out exceptionally fast. Carbide is essential for maintaining tool life and part quality.

- Tight Tolerance Requirements: For any application demanding high precision and part-to-part consistency, carbide is the only choice to maintain those tolerances over a long production run.

- Minimizing Downtime is a Priority: In lean manufacturing environments or when operating at near-full capacity, the reduction in downtime offered by carbide tooling is a massive competitive advantage.

- Automated Production Lines: In fully automated setups, unscheduled stops for tool changes are particularly disruptive and costly. The reliability of carbide is critical for “lights-out” manufacturing.

Making the Right Choice: Partnering with an Expert Die Manufacturer

The performance of a carbide die is not just about the material itself; it’s also about the expertise behind its design and fabrication. The correct grade of carbide, the precision of the grinding and polishing, and the design of the die’s geometry all play a critical role in its ultimate performance and lifespan. Partnering with an experienced manufacturer like Xiluomold ensures that you are not just buying a tool, but investing in a solution engineered for your specific application. An expert partner can help you select the right carbide grade and design to maximize your ROI and achieve your production goals.

Conclusion: Shifting Perspective from an Expense to a Strategic Investment

So, are carbide heading dies worth the investment? The evidence is overwhelming. By looking past the initial purchase price and focusing on the Total Cost of Ownership, it becomes clear that for serious manufacturing operations, carbide is not an *expense*—it is a *strategic investment* in productivity, quality, and profitability. The reduction in downtime, labor costs, and material waste, combined with the increase in production speed and product consistency, provides a powerful and lasting return that makes the higher upfront cost a smart, forward-thinking business decision.

Frequently Asked Questions (FAQ)

1. How much longer do carbide heading dies last compared to steel dies?

Depending on the application, material being formed, and machine conditions, a carbide die can last anywhere from 10 to 50 times longer than a standard tool steel die. For high-volume runs, this can be the difference between changing a die daily versus monthly.

2. Can carbide dies be repaired or reworked?

Yes, in many cases. High-quality carbide dies can be re-polished or re-ground to extend their usable life, further enhancing their long-term value. This requires specialized equipment and expertise, which an experienced die manufacturer can provide.

3. Is there any situation where a tool steel die is better?

Tool steel dies may be a more cost-effective choice for extremely short production runs, prototyping, or when working with very soft, non-abrasive materials where tool wear is not a significant factor. For any form of mass production, carbide is almost always superior.

4. What is the main cause of carbide die failure?

While extremely hard, carbide is more brittle than steel. The most common cause of premature failure is not wear, but chipping or cracking due to improper machine setup, shock loading, or misalignment. Proper operator training and machine maintenance are crucial to maximizing the life of carbide tooling.